Our integrated robotic workplaces produce materials with a faultless quality of welds. Track accuracy of these robots is guaranteed by unique combination of controlling and mechanics, thanks to which we produce high quality work pieces ready to serve their purpose immediately.

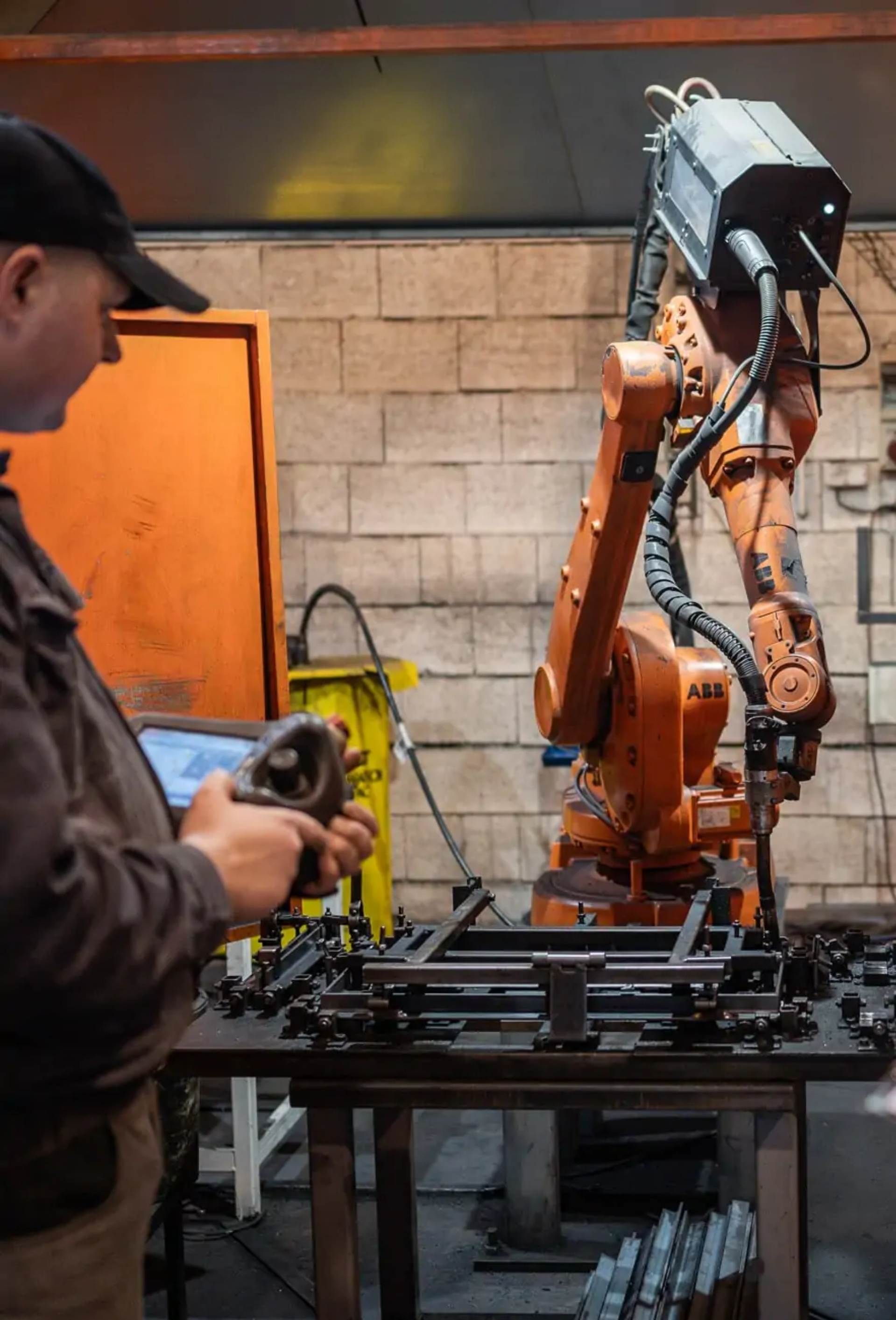

WELDING WITH ROBOT ABB IRB 1600

Robot ABB IRB 1600 is a guarantee of quality, speed and accuracy. It is characterized by high performance and shorter timing of individual cycles. In comparison with other robots, ABB IRB 1600 can work twice as fast. Although the worktime is shorter, the accuracy and quality of welding seams is retained. Using the robot considerably increases the effectiveness of production and reduces the costs.

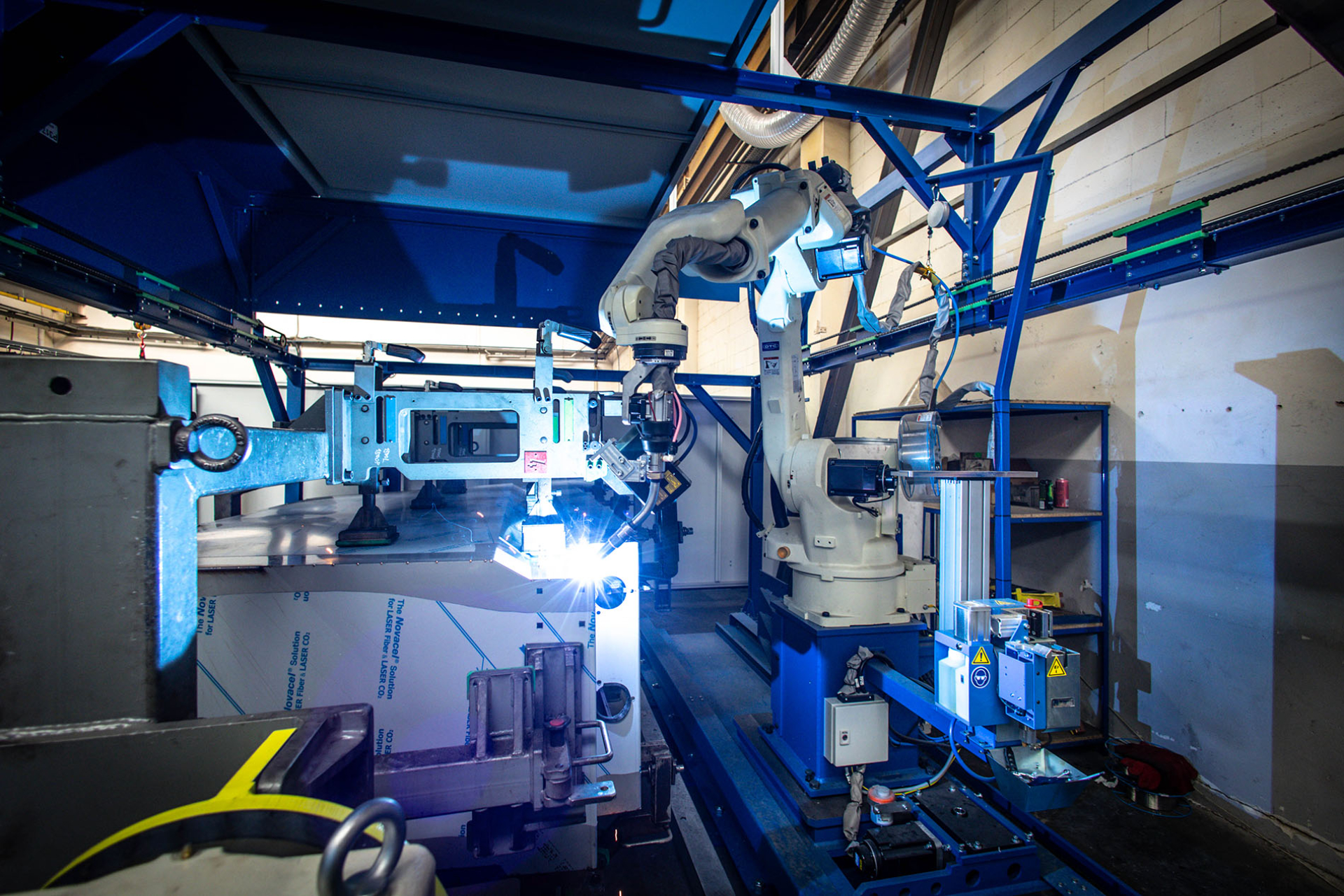

OTC DAIHEN FD-B6L WELDING ROBOT

Thanks to a long arm, it is best suited for large structures. Its key features and benefits are as follows:

- Faster Cycle Time - the cycle times are reduced thanks to the fastest speeds in the industry.

- Slim design - 30% reduction in area compared to current models.

- User-friendly operation - designed to avoid adverse influences behind the arm (all cables required for welding with synchro feed are already built into the robot).

- More solid design - the maximum load capacity is 6 kg and the robot is suitable for the handling of applications. It can be equipped with various welding accessories and sensors.

A2PF501 two axis positioner- 500kg

High-speed movement contributes to increased production efficiency! The maximum rotation speed of the tilt axis has been increased 2.5 times. Compared to a conventional machine, a 2-fold payload of 300 kg was achieved.

The OTC Daihen robotic welding accessories are produced by one manufacturer of all crucial components (robot, positioning and welding technology); this ensures 100% compatibility of the entire workplace and guarantees unrivaled technical perfection of the technological equipment in terms of mutual communication of these components, comfort and programming options and a perfect spatter-free welding process with the possibility of changing parameters at the beginning, end and during welding.